|

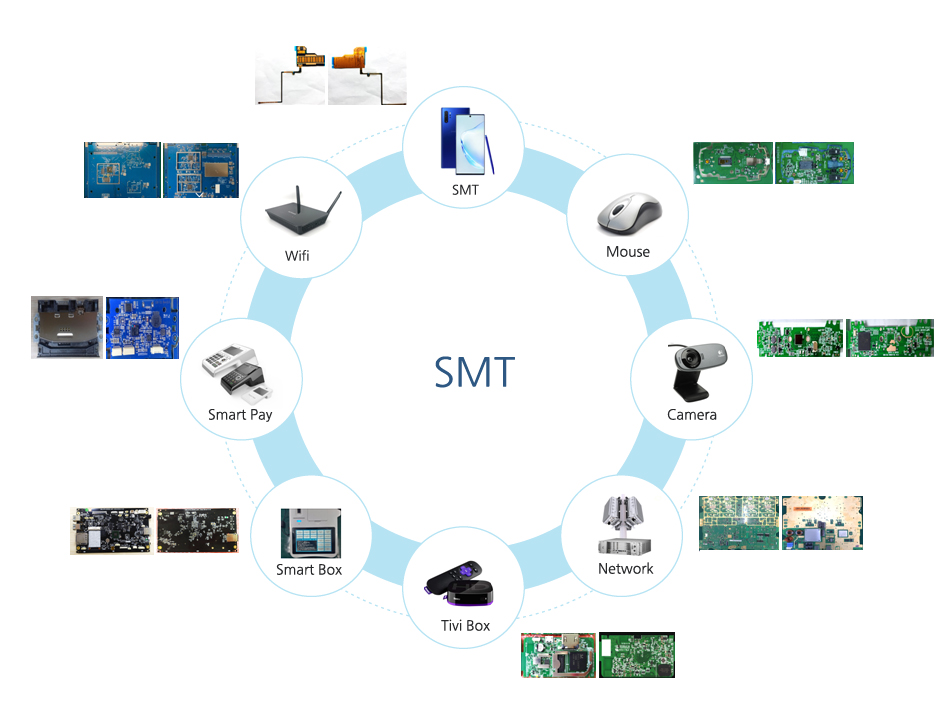

| SMT |

SYNOPEX manufacturing process can produce SMT components such as key-PBA for mobile FPCB (Flexible Printed Circuit Board), bio touch sensor module, camera module, wireless, communication module, IT devices module and other applicable .

|

SMT production process for FPCB SMT production process for FPCB

|

|

|

SMT is a technology inserting components on the board by automatic devices on the line. The production line with the high-end machines, professional and enthusiastic team has created the perfect products to provide to the market.

|

|

|

1. Insert FPCB

|

|

- Checking F-PCB code

- Insert FPCB into Carrier/JIG

|

|

|

|

|

|

2. Printer

|

|

- Prepare Solder Scream

- Prepare metal Mask

- Prepare Squezze

- Setting printing mode, programme

|

|

|

|

|

|

3. SPI

|

|

- Setting checking mode as standard

- Check status of board after printed

|

|

|

|

|

|

4. Mounter

|

|

- Check LCR

- Confirm exact component

- Input components from reel or tray to board

|

|

|

|

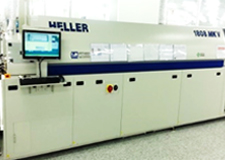

5. Reflow

|

|

- Use reflow oven technology

- Set-up temperature, time, oxy concentration

|

|

|

|

|

|

6. AOI

|

|

- Check component mouting status by automatical optic.

- Check weld quality, plugging status, reading values.

|

|

|

|

|

|

7. Auto Marking

|

|

- Read data from AOI machine based on set-up coordinates

- Dot error points that AOI machine found.

|

|

|

|

|

|

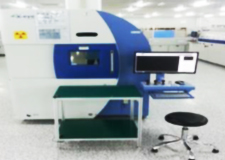

8. Xray

|

|

- X-ray inspection.

- Check for open or breaked point, air bubbles inside the weld, hidden locations.

|

|

|

|

9. Press

|

|

- The process of using molds to create products.

- Large cutting speed.

- High precision.

|

|

|

|

|

|

10. SMT Complete

|

|

- Finish the SMT process, go to the stage of finishing the circuit board.

- Complete SMT step, move to circuit finishing stage.

|

|

|

|

SMT production process with Rigid PBA SMT production process with Rigid PBA

|

|

|

SMT is a technology inserting components on the board by automatic devices on the line. The production line with the high-end machines, professional and enthusiastic team has created the perfect products to provide to the market.

|

|

|

1. IQC

|

|

- Check PCB code

- Input PCB to Carrier/JIG/ Magazine

- Check Metal Mask, JIG

|

|

|

|

|

|

2. PRINT

|

|

- Prepare Solder Scream

- Prepare metal Mask

- Prepare Squezze

- Setting printing mode, programme

|

|

|

|

|

|

3. SPI

|

|

- Setting checking mode as standard

- Check status of board after printed

|

|

|

|

|

|

4. Mounter

|

|

- Check LCR

- Confirm exact component

- Input components from reel or tray to board

|

|

|

|

5. MOI

|

|

- Check component mouting status by automatical optic.

- Check weld quality, plugging status, reading values.

|

|

|

|

|

|

6. Reflow

|

|

- Use reflow oven technology

-Set-up temperature, time, oxy concentration

|

|

|

|

|

|

7. AOI

|

|

- Check component mouting status by automatical optic.

- Check weld quality, plugging status, reading values.

|

|

|

|

|

|

8. Xray

|

|

- X-ray inspection.

- Check for open or breaked point, air bubbles inside the weld, hidden locations.

|

|

|

|

9. Wave Solder

|

|

- Using wave soldering technology to attach piercing components

- Setting Flux spraying time, wave height, ...

|

|

|

|

|

|

10. OQC

|

|

- Check the welding status, appearance of the CHIP, IC

- Check apprearance of Assy assembly

|

|

|

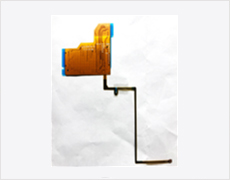

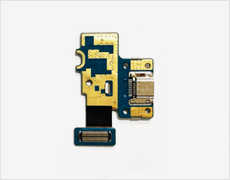

Typical SMT products Typical SMT products

|

|

BOT side |

TOP side |

BOT side |

TOP side |

BOT side |

TOP side |

BOT side |

TOP side |

|

|

|

|

Business

Business

SMT production process for FPCB

SMT production process for FPCB